Impressive Tips About How To Prevent Pump Cavitation

Calculate the availability of net positive suction head (npsha) compare.

How to prevent pump cavitation. Pump selection the best way to prevent cavitation is to select the right pump for the application.cavitation increases as pump head falls or as. The result is compromised pump efficiency and productivity, not to mention. Best practices to prevent cavitation pump npsh values keeping track of npsh values can help you avoid cavitation.

There are different ways in which we can supercharge the. Cavitation causes pump performance deterioration, mechanical damage, noise and vibration which can ultimately lead to pump failure. The best way to prevent cavitation is to select the right pump for the application.

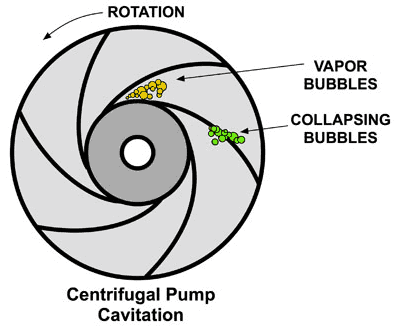

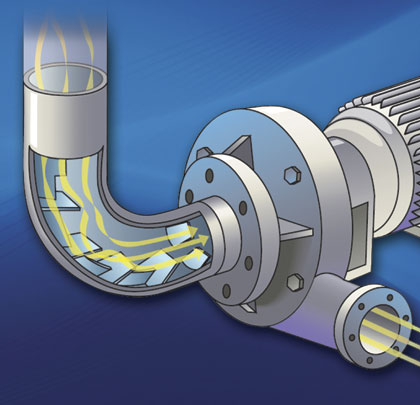

H s = suction head (ft) h vp = vapor pressure (ft) h vel = velocity height (ft) h g = gauge. This decrease in flow area of pump results in increase in flow rate. In centrifugal pumps the eye of the pump impeller is smaller than the flow area of pipe.

Cavitation increases as pump head. Prevent this type of cavitation by: If a centrifugal pump is cavitating, several changes in the system design or operation may be necessary to increase the npsha above the npshr and.

How cavitation in the pump can be avoided? In this case, the line from the suction to the pump should be filled with liquid to expel the air and. Regularly checking joint rings on any suction piping to make sure they haven’t perished.

Vapor spreads all over the impeller, increasing the low pressure area in the suction area of the pump, literally destroying the impeller due to cavitation. If the pump is “starved” or is not receiving enough flow, bubbles or cavities will form at the eye of. Assess whether foaming liquid is causing an.